MRP System: The Ultimate Guide to Benefits – In the fast-paced world of manufacturing and supply chain management, an efficient Material Requirements Planning (MRP) system is vital for optimizing production processes. An MRP system helps businesses manage inventory, production schedules, and procurement, ensuring that the right materials are available at the right time. In this guide, we’ll dive deep into the MRP system, highlighting its benefits, top products, use cases, and how to make the right purchasing decisions for your business.

What is an MRP System?

A Material Requirements Planning (MRP) system is a software-based tool that helps businesses plan and manage manufacturing processes. By integrating data from inventory management, production schedules, and procurement needs, MRP systems allow manufacturers to streamline their operations, reduce waste, and ensure the timely delivery of products. 🚀

Key Features of an MRP System:

- Inventory Management: Helps track raw materials, work-in-progress items, and finished goods.

- Production Scheduling: Automates the creation of production schedules based on demand forecasts and supply availability.

- Demand Forecasting: Uses historical data to predict future material requirements, reducing overstocking and stockouts.

- Procurement Management: Determines the optimal time to purchase materials, preventing delays in production.

- Bill of Materials (BOM): Assists in managing complex product structures and ensures all necessary materials are available.

By leveraging these features, an MRP system helps companies stay ahead of production demands, optimize inventory, and reduce operational costs.

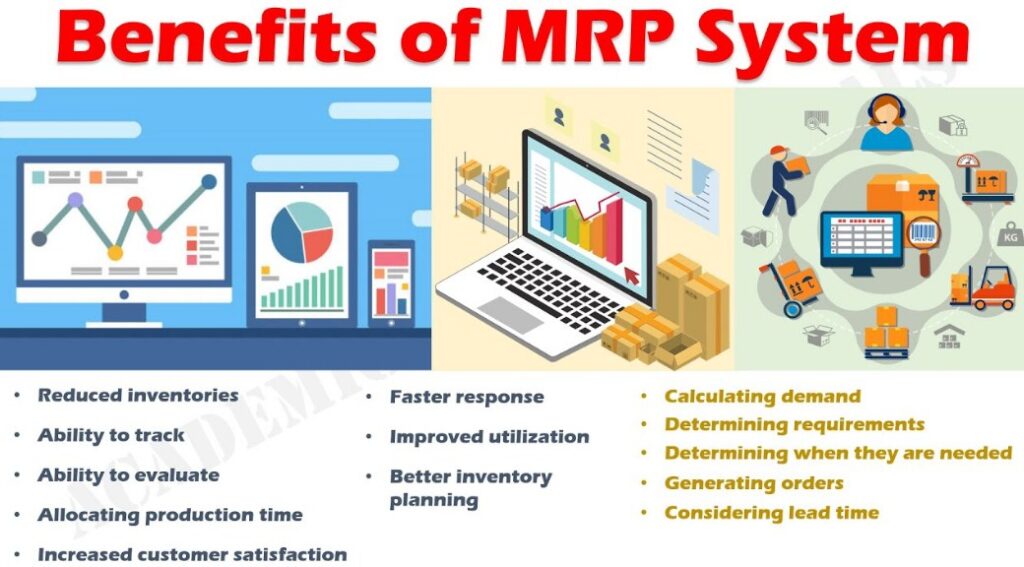

Benefits of Using an MRP System

The adoption of an MRP system can transform the efficiency of your manufacturing or production operations. Here are the main benefits:

1. Increased Efficiency and Productivity

By automating material tracking, production schedules, and procurement processes, MRP systems reduce manual work, which increases overall productivity. This automation ensures that manufacturers can focus more on high-priority tasks while the system handles routine operations.

2. Optimized Inventory Management

An MRP system ensures that materials are available when needed, helping to prevent overstocking and understocking situations. This optimization not only saves money but also improves cash flow by reducing excess inventory costs.

3. Improved Production Planning

MRP systems provide accurate, real-time data to help plan production more effectively. By analyzing demand forecasts, manufacturers can schedule production based on actual needs, ensuring that resources are used efficiently.

4. Cost Reduction

With better control over materials and production schedules, companies can avoid costly mistakes, reduce waste, and cut down on unnecessary procurement. This directly contributes to cost savings and improved profitability.

5. Enhanced Customer Satisfaction

With an MRP system in place, production can be completed on time, helping businesses meet customer deadlines consistently. This improves customer trust and satisfaction, leading to stronger long-term relationships.

Top MRP System Products for 2025

There are several MRP systems on the market, each tailored to different types of businesses. Below are five MRP software products that stand out in 2025, based on performance, features, and real-world application.

1. SAP Business One MRP

Overview: SAP Business One is a comprehensive ERP solution designed for small and medium-sized businesses. Its MRP module offers detailed planning, production scheduling, and inventory management features.

Features:

- Integrated MRP, production scheduling, and inventory management.

- Customizable to meet specific business needs.

- Real-time inventory visibility and forecasting tools.

Pros:

- Seamlessly integrates with other SAP ERP modules.

- Offers robust reporting tools for better decision-making.

Cons:

- High initial setup cost.

- Requires training for new users.

Price: Contact for a quote.

Best For: Small to medium-sized manufacturers who need a comprehensive, integrated solution.

2. Oracle NetSuite MRP

Overview: Oracle NetSuite offers an advanced MRP system as part of its cloud-based ERP suite, ideal for growing businesses that need more scalability.

Features:

- Cloud-based for remote access and scalability.

- Predictive analytics for better demand planning.

- Real-time data sync across all departments.

Pros:

- Highly customizable.

- Strong financial and accounting integration.

Cons:

- Expensive pricing structure for smaller businesses.

Price: Starting at $999/month.

Best For: Growing businesses looking for a cloud-based solution with advanced capabilities.

3. Microsoft Dynamics 365 for Manufacturing

Overview: Microsoft Dynamics 365 is a powerful MRP system that combines finance, operations, and production management in one platform.

Features:

- Built-in artificial intelligence (AI) for demand forecasting.

- Integration with other Microsoft services like Office 365.

- End-to-end visibility into manufacturing processes.

Pros:

- Seamlessly integrates with other Microsoft products.

- Cloud-based with strong data security.

Cons:

- Complex setup process.

- High cost for small businesses.

Price: Contact for a quote.

Best For: Large enterprises with complex manufacturing needs.

4. MRPeasy

Overview: MRPeasy is a user-friendly MRP system designed for small and medium-sized manufacturers. It provides a cost-effective solution with an intuitive interface and strong features.

Features:

- Easy-to-use interface.

- Multi-currency support for international businesses.

- Real-time production tracking.

Pros:

- Affordable pricing for small businesses.

- Quick implementation and onboarding.

Cons:

- Limited customization options.

- Basic reporting features compared to competitors.

Price: Starting at $39/month.

Best For: Small manufacturers looking for an easy-to-implement, cost-effective MRP solution.

5. Infor CloudSuite Industrial (SyteLine)

Overview: Infor CloudSuite is an industrial-grade MRP system that offers deep functionality for manufacturing, procurement, and supply chain management.

Features:

- Industry-specific functionality for manufacturing.

- Predictive analytics and AI-driven insights.

- Cloud-based for flexibility and scalability.

Pros:

- Highly scalable.

- Strong supply chain management features.

Cons:

- Steep learning curve.

- Expensive implementation costs.

Price: Contact for a quote.

Best For: Large-scale manufacturers looking for deep, industry-specific MRP capabilities.

MRP System Comparison Table 📝

| Product | Use Case | Pros | Cons | Price | Features |

|---|---|---|---|---|---|

| SAP Business One MRP | Small and medium manufacturers | Comprehensive integration, real-time inventory | Expensive setup, requires training | Contact for quote | Inventory management, production scheduling |

| Oracle NetSuite MRP | Growing businesses | Cloud-based, predictive analytics | Expensive for small businesses | $999/month | Demand forecasting, real-time data sync |

| Microsoft Dynamics 365 | Large enterprises | Seamless integration with Microsoft services | Complex setup, high cost | Contact for quote | AI for demand forecasting, end-to-end visibility |

| MRPeasy | Small manufacturers | Affordable, easy to use | Limited customization | $39/month | Real-time tracking, multi-currency support |

| Infor CloudSuite | Large-scale manufacturers | Scalable, strong analytics | Steep learning curve, expensive | Contact for quote | Predictive analytics, supply chain management |

Where and How to Buy an MRP System

Choosing the right MRP system depends on your business size, needs, and budget. Here’s a quick guide on how to purchase an MRP system:

- Determine Your Needs: Identify your business requirements, including production volume, budget, and scalability.

- Request a Demo: Most MRP systems offer free trials or demos. Take advantage of these to understand the system’s capabilities.

- Consult with Vendors: Contact sales teams to get tailored quotes and support.

- Compare Pricing and Features: Use the comparison table above to assess which product best fits your needs.

You can buy directly from the vendor websites, such as:

- SAP Business One MRP

- Oracle NetSuite MRP

- MRPeasy

Some systems also have partners or resellers, so you can reach out for additional support.

5 FAQ About MRP Systems

- What is an MRP system used for?

- An MRP system is used to manage manufacturing processes, including inventory management, production scheduling, and procurement, ensuring that materials are available when needed.

- What are the benefits of implementing an MRP system?

- Key benefits include increased efficiency, optimized inventory, cost reduction, improved production planning, and enhanced customer satisfaction.

- Can an MRP system help with supply chain management?

- Yes, most MRP systems integrate with supply chain management to forecast material needs, manage supplier relationships, and track inventory levels.

- How do I choose the best MRP system for my business?

- Consider factors like your business size, production requirements, scalability, and budget. Use demos and compare features to make an informed decision.

- How much does an MRP system cost?

- Prices vary depending on the software and your business needs. For small businesses, it can cost as little as $39/month, while larger enterprise solutions can range from hundreds to thousands of dollars per month.

By understanding the features, benefits, and use cases of an MRP system, you can make an informed decision on which product will best meet the needs of your business. Don’t hesitate to contact the vendors or take advantage of free demos to explore your options.

Read More >>>

- Business Life Cycle Stages in Order: Key Phases, Benefits & Products to Enhance Your Journey

- Understanding the Business Life Cycle Stages: A Comprehensive Guide for Success with GTMetrix